Precision Weed Control with IoT and AI

Weeds cost U.S. farmers billions annually in herbicides and labor. Traditional methods blanket fields with chemicals or rely on time-intensive manual weeding, both of which are expensive and harmful. Enter precision weed control: advanced IoT sensors and AI-powered systems that target weeds directly. These technologies cut herbicide use by up to 98%, improve accuracy to 95–99%, and reduce labor costs by up to 85%. They also help farmers maintain yields while addressing growing concerns over chemical use.

Key advancements include:

- Herbicide GUSS: Autonomous orchard sprayer using GPS and AI for spot spraying, saving up to 90% on herbicides.

- Verdant Robotics Sharpshooter: High-precision system identifying weeds as small as 0.08 inches, slashing herbicide use by 96–98%.

- Solix Ag Robotics: Solar-powered robots that monitor crops and reduce herbicide use by 95–98%.

- FarmDroid FD20: Dual-purpose, solar-powered robot for seeding and weeding, cutting chemical use by up to 94%.

These systems are transforming farming by reducing costs, improving efficiency, and meeting rising demands for chemical reduction. While upfront costs are high, long-term savings and productivity gains make them increasingly viable, especially for medium and large farms.

Using Drones & AI for Precision Weed Mapping and Spraying - WA Wheat Farm

1. Herbicide GUSS

Herbicide GUSS is a prime example of how IoT and AI can work together to transform orchard weed control. Developed by GUSS Automation, this fully autonomous machine combines cutting-edge technologies to deliver precise and efficient weed management. Let’s dive into the technology, efficiency, and design that make Herbicide GUSS a standout solution.

Technology Used

Herbicide GUSS relies on a combination of GPS, LiDAR, and advanced software to navigate orchard floors autonomously [3]. Its nine-sensor system is designed to detect and target weeds with pinpoint accuracy [5][6]. The AI-driven weed detection system can even identify weeds as small as 2–3 leaves during early growth stages [4]. This smart detection system not only ensures precise spraying but also reduces material use and minimizes chemical drift [2][5].

Herbicide Savings

One of the most striking advantages of Herbicide GUSS is its ability to significantly cut herbicide usage. By employing a spot-spraying approach, the machine applies herbicide only where weeds are detected, leading to savings of up to 90% depending on weed density [7][8]. This targeted method allows growers to maintain effective control while using far fewer chemicals compared to traditional methods.

Operational Scale

Herbicide GUSS is built for large-scale operations. A single operator can remotely manage up to eight machines simultaneously [7][8]. The Electric GUSS model measures 23′6″ in length and 6′4″ in height, with an adjustable operational width between 8′4″ and 19′ [7][8]. Its hydraulic spray booms, which can be adjusted for height and tilted for berm spraying, accommodate row spacings from 18′ to 22′ [7][8]. Additionally, the diesel-powered Orchard GUSS and mini GUSS models can be upgraded with the Smart Apply precision system, further enhancing their capabilities [7][8].

Cost Efficiency

Herbicide GUSS offers considerable cost and safety benefits. Its autonomous operation and precision spraying reduce both labor and material expenses. With one operator managing multiple machines, efficiency is further amplified. Safety is another key feature, with automatic hazard detection and spray pausing to ensure operations are safe, even when people are nearby. These features make Herbicide GUSS a practical and efficient choice for modern farming [7][8].

"Our growers have been asking for an autonomous herbicide machine. We took that concept to the next level by implementing weed detection technology to give the grower a machine that provides immense value. Lower chemical usage helps the grower reduce costs and is a benefit to the environment."

– Gary Thompson, COO at GUSS Automation [5]

2. Verdant Robotics Sharpshooter

The Verdant Robotics Sharpshooter combines cutting-edge AI and advanced hardware to deliver precise, split-second herbicide applications. Designed for speed and accuracy, it adapts seamlessly to various farming operations, improving weed control efficiency on a whole new level.

Technology Used

At the core of the Sharpshooter is its "Bullseye Aim & Apply Technology", which harnesses Spatial AI, machine learning, and Aiming‐Nozzle technology. Ultra-high-resolution cameras scan field segments roughly 40 by 20 inches in size, capturing detailed imagery to distinguish crops from weeds through sophisticated computer vision algorithms. Once identified, rotating nozzles fire between 120 and 480 targeted shots per second, with 99% of them landing within 0.2 inches of the target.

The system also includes advanced features like Crop Band Zone detection, 3D Crop Shield, Plant-line Detection, Adaptive Spray Size, and Customizable Safety Buffers. These tools enable the Sharpshooter to tackle weeds as small as 0.08 inches and as large as 24 inches (2 feet), ensuring unparalleled precision in weed management.

Herbicide Savings

One of the Sharpshooter’s standout achievements is its ability to cut herbicide use by an impressive 96–98%. By targeting only weeds and sparing crops, it minimizes chemical waste while dramatically reducing hand-weeding costs by 65%. Its application system is so precise that it can spray areas as small as 0.67 inches, ensuring herbicides are applied exactly where they’re needed - nowhere else.

Operational Scale

Built for flexibility, the Sharpshooter can cover up to 5 acres per hour in almost any farming condition, making it suitable for a wide array of crops and farming systems, including organic, no-till, and conventional setups. It delivers up to 270 pinpoint shots per second across more than 20 crop types.

Farm Manager Jason Gaylord at My-T Acres in Batavia, New York, shared his experience with the Sharpshooter in May 2025:

"Even before putting it to work, we could see how easily it integrates into our operation and how much ground we'll be able to cover without rethinking our whole system."

This adaptability translates into significant operational savings and efficiency.

Cost Efficiency

The Sharpshooter doesn’t just save on herbicides - it also slashes labor costs. It attaches easily to any 5-series tractor using a standard 3-point hitch, eliminating the need for specialized equipment. Farms that once relied on large crews can now accomplish the same tasks with just one machine and one operator.

Daniel Alameda from TopFlavor Farms highlighted the efficiency gains:

"What used to take 30 people all day can now be done with one machine and one operator. From the driver's seat, you see everything in real time – the crop, the weeds, and the machine taking action."

Durability tests show the Sharpshooter can perform flawlessly for over three years under normal conditions, making it a reliable long-term investment. As CEO Gabe Sibley put it:

"The Sharpshooter delivers significant savings, cutting chemical inputs by over 96% and reducing hand-weeding costs by an average of 65%."

🚀 Ready to Reinvent Your Garden?

Join thousands of homeowners who have transformed their gardens using our AI design tool. Upload one photo to explore endless possibilities.

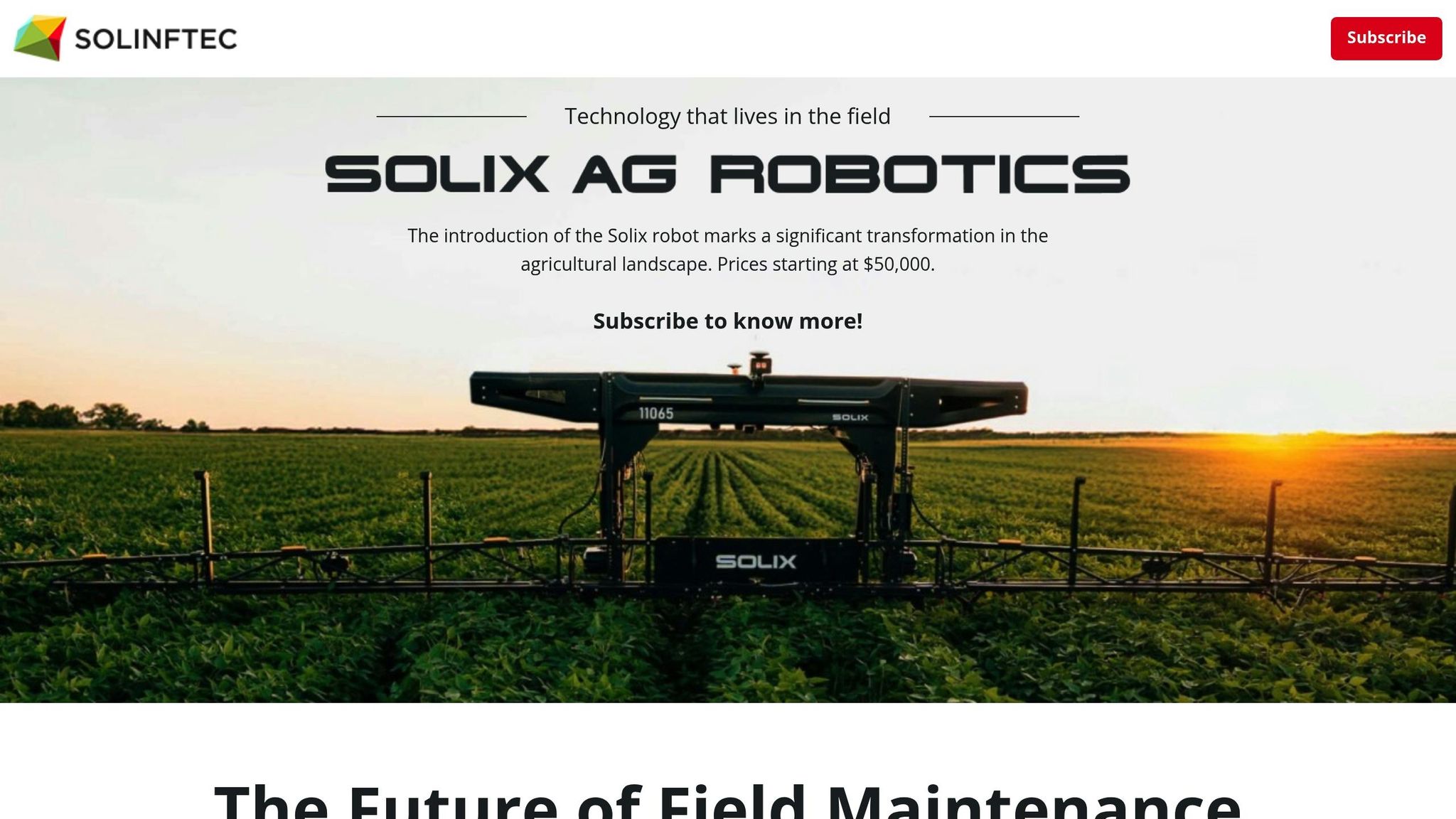

Get your AI garden designs →3. Solix Ag Robotics

Solix Ag Robotics brings a solar-powered solution to precision farming, focusing on advanced weed control and crop monitoring. By combining autonomous robots with their ALICE AI technology, Solix offers a system that not only targets and sprays weeds but also assesses crop health, tracks emergence patterns, monitors population density, and evaluates growth stages across expansive fields.

Technology Used

At the heart of Solix's innovation is ALICE AI, which utilizes vision cameras and sensors to navigate fields autonomously. This system identifies crops, differentiates them from weeds, and applies herbicides with pinpoint accuracy.

The robots are equipped with an intelligent docking station that selects herbicides based on real-time weed identification. Guilherme Guiné, COO for North America, explains:

"We designed the docking station to allow Solix to choose the product that will be used based on the recognition of weeds by our artificial intelligence system, ALICE AI, enabling the use of specific products for each unique situation."

The solar-powered robots operate continuously, even in low-light conditions, with the capability to function for up to three days without direct sunlight. This ensures weeds are targeted during their most vulnerable early growth stages, maximizing effectiveness while minimizing crop disturbance.

Herbicide Savings

One of Solix's standout achievements is its ability to drastically reduce herbicide use. The robots have demonstrated up to a 98% reduction in herbicide volume, with 95% savings during post-emergence applications and 92% during pre-planting operations.

In the 2024 growing season, 50 Solix Sprayer Robots applied just 15,089 gallons of product while conserving 72,000 gallons of water. Some fields achieved as much as 97% optimization of herbicide use through the Solix system.

The technology's effectiveness was validated in 2023, when partnerships with Co-Alliance, Carroll Service Company, and Premier Ag led to over 95% reductions in herbicide usage during the crop season. By eliminating weeds early, these farms saw significant resource savings.

Operational Scale

Designed for large-scale farming, Solix robots can monitor 2 million plants daily while delivering real-time agronomic insights. Each robot can cover between 49 and 79 acres per day, with certain configurations managing up to 96 acres depending on field conditions.

The system supports major grain crops like corn, soybeans, cotton, and wheat, making it versatile for different farming operations. During its first commercial season, Solix robots monitored over 65 million plants across farms in Indiana and Illinois, showcasing their capability to scale for extensive agricultural use.

Cost Efficiency

Solix robots also help reduce operational costs by cutting fuel and labor expenses. Their solar-powered design eliminates fuel costs entirely, while their autonomous functionality reduces the need for manual labor. Continuous operation allows farmers to cover more ground with fewer resources.

Taylor Wetli, U.S. Commercial & Business Development Manager at Solinftec, highlights the benefits:

"The Solix Sprayer Robot offers farmers increased efficiency, precision application, data-driven insights, and eco-friendly farming practices."

Results from the 2024 deployment underline these advantages. Farms using Solix achieved up to a 98% reduction in herbicide use and saw potential yield increases of up to 10% in crops like wheat, corn, popcorn seed, and soybeans. This combination of cost savings and improved yields makes Solix a valuable tool for large-scale farming operations.

sbb-itb-4d6a8dd

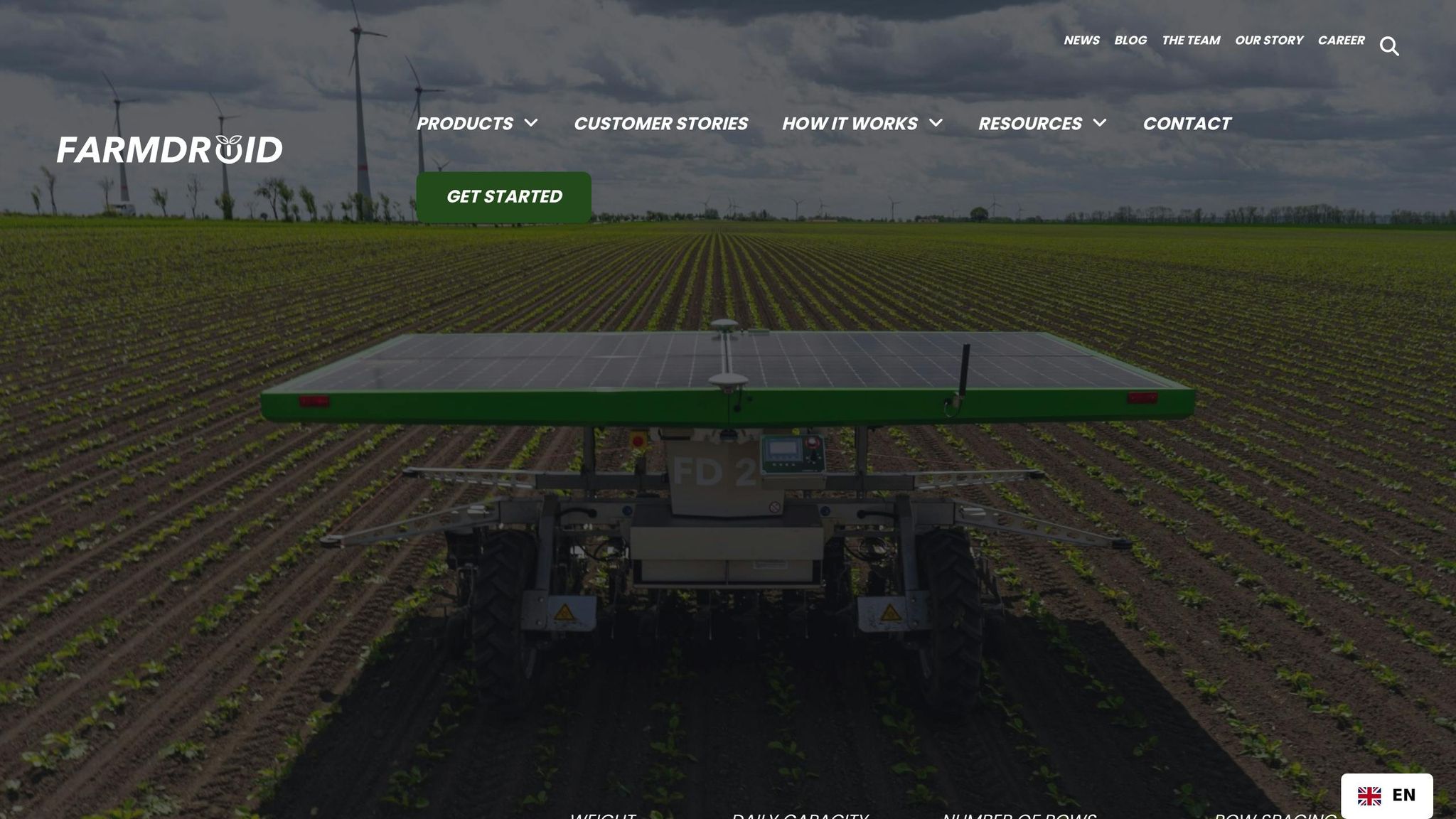

4. FarmDroid FD20

The FarmDroid FD20 takes precision weed control to the next level by combining solar power with advanced RTK GPS technology. Designed in Denmark, this autonomous robot handles both seeding and weeding, making it a dual-purpose tool for farmers. With over 500 units sold across 20+ countries, it has become the top-selling solar-powered field robot worldwide [13].

Technology Used

At the heart of the FD20 is its highly accurate 8 mm (0.31 in) RTK GPS system, which records the exact position of each seed during planting [10]. This precise mapping allows the robot to perform both inter-row and intra-row weeding without damaging nearby crops [10]. The FD20 operates with two key systems: the +Weed system for mechanical weeding and the optional +Spray system, which uses Pulse Width Modulation (PWM) electric nozzles for precise micro-spraying of crop protection products [11]. Farmers can track the robot’s progress and receive updates through the FarmDroid app, ensuring smooth and autonomous operation [10].

Herbicide Savings

The FD20 delivers impressive reductions in chemical use. Its +Spray system can cut herbicide usage by up to 94% [10][11]. In 2023, field trials in Germany, conducted by Südzucker in collaboration with Amazone, combined mechanical hoeing with spot spraying. This approach - five rounds of hoeing and two spot sprayings - lowered herbicide use by 86% while maintaining effective weed control [12]. For farms relying solely on mechanical weeding, the FD20 can eliminate pesticide use entirely, with trials showing an average of 97% weed control across four tests [12][13].

Operational Scale

The FD20 is designed for fields up to 50 acres (20 hectares) but has been successfully used on areas as large as 99 acres (40 hectares) [14][16]. René Jørgensen, CEO of FarmDroid, shared:

"Farmers have said they had success with larger areas than 20 hectares. We are looking to expand that with new designs." [15]

Under optimal conditions, the FD20 can cover up to 5 hectares (around 12 acres) per day, moving at speeds between 0.3 and 0.6 mph (roughly 25–52 feet per minute) [16][15]. It supports up to 12 rows with row spacing starting at 22.5 cm (about 8.9 inches), making it adaptable to a variety of crops [16]. The robot’s design allows it to remain in the field without frequent relocation. As Jørgensen explains:

"That's the whole concept, to free the farmers from manual weeding [...] If you don't need to move it, you can just leave it there." [14]

Additionally, multiple FD20 robots can work together, with one handling seeding while another takes care of weeding [10].

Cost Efficiency

With a price tag of around €65,000 (approximately $70,000), the FD20 offers significant cost savings [14]. Its solar-powered system eliminates fuel costs, and its autonomous operation drastically reduces labor needs. In German trials, manual weeding labor dropped from 67 hours per hectare (27 hours per acre) in untreated plots to just 10–13 hours per hectare (4–5 hours per acre) with the FD20 - an 80–85% reduction [12]. Moreover, autonomous weeding preserved yields at about 90 tons per hectare (36 tons per acre), compared to 71.5 tons per hectare (29 tons per acre) in untreated plots, representing a 26% yield increase [12].

René Jannick Jørgensen highlighted the economic and environmental benefits:

"We are incredibly proud to have closed this investment, which will strengthen FarmDroid's position and provide opportunities to develop and expand the use of agricultural robots. This investment contributes both with competences and financial resources dedicated to scaling the business, increasing our impact, and promoting sustainable and economically attractive solutions for agriculture." [13]

The FD20’s ability to operate on various terrains - provided they are not rocky, muddy, or flooded - makes it a versatile tool for both ecological and conventional farming systems. Its flexibility ensures reliable performance across diverse farming conditions.

Advantages and Disadvantages

Precision weed control systems bring a mix of benefits and challenges to modern farming. Knowing these trade-offs is essential for farmers to pick the right technology for their unique needs and goals.

Shared Benefits of Precision Systems

Across the board, precision weed control technologies deliver measurable savings on herbicide use and costs. For example, AI-driven weed management can reduce chemical usage by up to 70% [1]. This not only helps mitigate rising chemical prices but also addresses environmental concerns. Each system, however, has its own way of balancing precision with operational scale.

Strengths of Individual Technologies

- Herbicide GUSS: Best suited for large-scale operations, this system prioritizes efficiency in broad-area spraying. However, it doesn’t match the pinpoint accuracy of newer technologies.

- Verdant Robotics Sharpshooter: Utilizes advanced computer vision to target individual weeds with impressive precision, making it ideal for precision-focused tasks.

- Solix Ag Robotics: Offers flexibility by combining mechanical cultivation and precision spraying, adapting to varying field conditions.

- FarmDroid FD20: Stands out with its solar-powered design and dual capabilities for seeding and weeding. This not only reduces fuel costs but also supports both inter-row and intra-row weeding.

Challenges and Limitations

While the benefits are clear, there are hurdles to consider:

- High Initial Costs: The upfront investment can be prohibitive, especially for smaller farms.

- Technical Complexity: Operating and maintaining these systems often requires specialized knowledge.

- Performance in Tough Conditions: Muddy, rocky, or flooded fields can significantly impact the effectiveness of these technologies.

Speed and Cost Factors

One key limitation is speed. Robotic hoeing, for instance, operates at a maximum of 0.6 mph, making it much slower than robotic spraying. This slower pace translates to treatment costs that are roughly double those of traditional broadcast herbicide applications [17]. However, robotic weeding achieves an efficacy rate of 87%, which is comparable to the 83% seen with broadcast methods, though it still comes with higher operational costs [17].

Economic and Long-Term Savings

Over time, AI-driven robotic systems could lead to significant savings. Farmers might see up to an 80% reduction in weed control costs, with industry estimates suggesting an annual savings of $2.5 billion in lost productivity [4].

Farm Size and System Suitability

The size of a farm heavily influences whether adopting these systems makes sense. Larger farms are better equipped to absorb the high upfront costs and reap the benefits of economies of scale [18]. Smaller farms, on the other hand, often face greater challenges in adopting these technologies, though precision sprayers are gradually becoming more accessible [4].

Balancing Environmental and Economic Goals

These systems strike a balance between reducing chemical use and managing costs. Smart sprayers, for instance, cut down on herbicide use, protect nearby crops, and minimize soil degradation [1]. Meanwhile, laser weeding offers a chemical-free alternative [1]. Despite the steep initial investment, rising herbicide prices make these solutions increasingly appealing. The agricultural AI market is expected to grow to $4.7 billion by 2028, reflecting growing adoption even amid financial challenges [4].

Ultimately, each system offers a unique approach to managing precision, cost, and operational needs. The best choice depends on factors like farm size, budget, technical expertise, and long-term sustainability goals.

Conclusion

The precision weed control industry is evolving to offer tailored solutions that cater to farms of all sizes. Choosing the right technology depends on understanding how these tools align with a farm's scale, budget, and operational needs.

Verdant Robotics Sharpshooter is a standout option for those seeking exceptional precision. With accuracy levels reaching up to 99% for weeds ranging from 0.08 inches to 24 inches, this system slashes chemical usage by as much as 99% and reduces labor costs by up to 85% [9]. Its "Aim & Apply" feature ensures precise weed targeting, making it a top choice for farms prioritizing efficiency and accuracy.

On the other hand, FarmDroid FD20 shines for its versatility and eco-friendly design. This solar-powered system operates carbon-neutral, covering up to 12 acres daily. Its dual functionality for seeding and weeding, along with RTK GPS precision for inter-row and intra-row tasks, makes it especially appealing for organic farms or those aiming to reduce their environmental impact. With compatibility across 50+ crop types and the ability to cut chemical use by up to 94% through targeted micro-spraying, it offers flexibility and sustainability [10].

Farm size significantly influences the adoption of these technologies:

- Small farms (under 100 acres) often face challenges with the high upfront costs of robotic systems. For these operations, satellite-based monitoring services provide a cost-effective alternative, offering AI-powered weed detection at $5–$10 per acre compared to traditional methods costing $25–$40 per acre [1].

- Medium-sized farms (100–500 acres) are well-positioned to adopt precision weed control tools. These farms can balance the initial investment with operational flexibility and scale, making systems like the FarmDroid FD20 an excellent fit for their needs.

- Large-scale farms (500+ acres) benefit the most from high-precision systems like the Verdant Robotics Sharpshooter. These operations can handle the higher investment costs while reaping substantial savings in chemical and labor expenses. The industry-wide potential savings of $2.5 billion annually in lost productivity highlight the transformative impact of these technologies [4].

As the agricultural AI market is projected to grow to $4.7 billion by 2028 [4], it’s clear that precision agriculture is more than just adopting new tools - it’s about creating a smarter, more efficient approach to farming. While the initial investment may seem steep, the long-term benefits of reduced chemical use, lower labor costs, and improved productivity make precision weed control an increasingly viable option for sustainable and profitable farming.

🎨 Visualize Your Dream Garden Today!

Transform any outdoor space into a professional landscape design in minutes. Just upload a photo, choose your style, and let our AI do the rest.

Start your garden transformation now →FAQs

How do IoT and AI technologies make weed control more sustainable and environmentally friendly?

How IoT and AI Are Transforming Weed Control

IoT and AI technologies are changing the game in weed management by using advanced sensors and smart algorithms to pinpoint and target weeds with incredible accuracy. The result? Herbicide usage can drop by as much as 70%, which means less contamination of soil and water. By zeroing in on specific problem areas, these tools also help save essential resources like water and fertilizers, making farming practices more efficient and eco-friendly.

But it doesn’t stop there. Beyond cutting down on chemicals, these technologies boost overall efficiency and reduce waste, which helps create a healthier environment. This approach is reshaping farming for the better, paving the way for practices that are not only effective but also kinder to the planet. Precision weed control is quickly becoming a cornerstone of sustainable agriculture.

What are the costs and savings for farmers using precision weed control systems like Herbicide GUSS or FarmDroid FD20?

Precision weed control systems, such as Herbicide GUSS and FarmDroid FD20, are transforming farming by significantly reducing costs and boosting efficiency. Take See & Spray, for instance - it has demonstrated herbicide cost reductions of up to 80%, which could translate into millions of dollars saved annually for larger farms. Other systems report average savings on herbicides ranging from 59% to 76%, roughly $6,500 per farm.

These savings aren't just limited to herbicide use. Farmers also benefit from lower fuel and labor expenses, as well as more precise application methods. By integrating these technologies, farms can cut costs while enhancing productivity and sustainability, making them a valuable tool for today’s agricultural operations.

How do Verdant Robotics SharpShooter and Solix Ag Robotics adapt to different farm sizes and conditions?

Verdant Robotics' SharpShooter stands out for its flexibility, offering solutions that can scale to fit farms of various sizes. With features like adjustable spray sizes and higher application rates, it works well for both smaller farms and larger operations.

On the other hand, Solix Ag Robotics is built with large-scale farming in mind. It can handle between 300 and 500 acres weekly, making it a solid choice for expansive agricultural areas. While the SharpShooter caters to farms of all sizes, Solix focuses on high-capacity operations designed for efficiency on a larger scale.

Related Blog Posts

Related Articles

Variable Rate Spraying: Key Performance Metrics

Explore how Variable Rate Spraying optimizes pesticide use, enhancing efficiency and sustainability while reducing costs and environmental impact.

How AI Predicts Seasonal Plant Diseases

Explore how AI predicts seasonal plant diseases using data analysis, enhancing crop health, and promoting sustainable gardening practices.

Top 5 AI Apps for Plant Care Reminders

Explore the top 5 AI apps that simplify plant care with personalized reminders, health diagnostics, and tailored advice for every gardener.

Growing Degree Days: AI's Role in Pest Control Timing

Explore how AI and Growing Degree Days enhance pest control timing, reducing pesticide use and increasing crop yields for sustainable agriculture.

IoT and AI for Disease Resistance Forecasting

Explore how IoT and AI are revolutionizing plant disease resistance forecasting, enhancing crop health and efficiency in agriculture.

Checklist for AI-Optimized Irrigation

Explore how AI irrigation systems enhance water efficiency, boost crop yields, and simplify garden management through smart technology.